“Gas Efficiency” research project of the Fraunhofer Institute for Physical Measurement Techniques IPM and MRT

Press release of the Fraunhofer Institute for Physical Measurement Techniques IPM

“New measuring system for natural gas – fast and accurate

The quality of natural gas is subject to strong fluctuations. This is not only due to varying natural gas deposits, but increasingly also to the feed-in of hydrogen from power-to-gas plants. For fuel gas analysis, Fraunhofer IPM, together with RMA Mess- und Regeltechnik GmbH & Co. KG has developed a measuring system that now also detects the hydrogen content in the gas in addition to the hydrocarbons it contains.

The calorific value of the gas fluctuates with its composition. The gas composition is an important factor for consumers, as the gas price is determined on the basis of the volume supplied and the calorific value. In industry, there is an additional aspect: The gas composition influences the combustion process. For example, if the proportion of hydrogen in the gas mixture increases, the calorific value decreases. If the gas flow – for example in a furnace – is then not adjusted, its temperature drops. Such fluctuations can lead to quality problems, for example in glass melting. Today, natural gas quality is usually determined using gas chromatographs at distribution points in the gas network or directly at the bulk consumer.

Infrared spectroscopy instead of gas chromatography

The EcoSpectro fuel gas measuring system, developed by Fraunhofer IPM on behalf of RMA Mess- und Regeltechnik GmbH & Co KG, determines the main components of natural gas spectroscopically: An infrared (IR) spectrometer detects the percentages of methane, ethane, propane, butane and longer hydrocarbon chains. Spectroscopy has several advantages over gas chromatography: Gas chromatographs are expensive, comparatively slow and complex to operate. The IR spectrometer, on the other hand, measures in sub-minute intervals, works for several months without recalibration and does not require purge gases. The spectra are analyzed using chemometric methods. In this way, gas concentrations of over 70 percent down to the 100 ppm range (parts per million) can be determined.

Hydrogen measurement via thermal conductivity

As part of the “Gas Efficiency” project, the IR spectrometer was equipped with an additional sensor system to determine the hydrogen content in order to detect regeneratively produced gases. As hydrogen cannot be detected by absorption spectroscopy with infrared light due to its molecular structure, a thermal conductivity sensor was added to the spectrometer. The thermal conductivity of hydrogen is a factor of seven greater than the thermal conductivity of all other fuel gases, including air, so the sensor reacts very sensitively to admixtures of hydrogen.

The modular sensor system was tested in the Fraunhofer IPM gas laboratory and then in a field test on a natural gas bypass at the Fraunhofer Institute for Solar Energy Systems ISE. There, the IR spectrometer and thermal conductivity sensor carried out a total of around 125,000 measurements. Over a period of several months – without hydrogen injection – the results matched the daily average calorific value values provided by the natural gas supplier very precisely. However, the measured values revealed fluctuations in gas quality in the minute range. Consumers who require consistent gas quality could therefore use the measuring system for rapid process control.

The changed H2 content could be determined with accuracies in the 100 ppm range at the times of hydrogen feed-in. The system is therefore particularly suitable as a fast-response measuring system for power-to-gas plants or consumers downstream of a hydrogen feed-in point

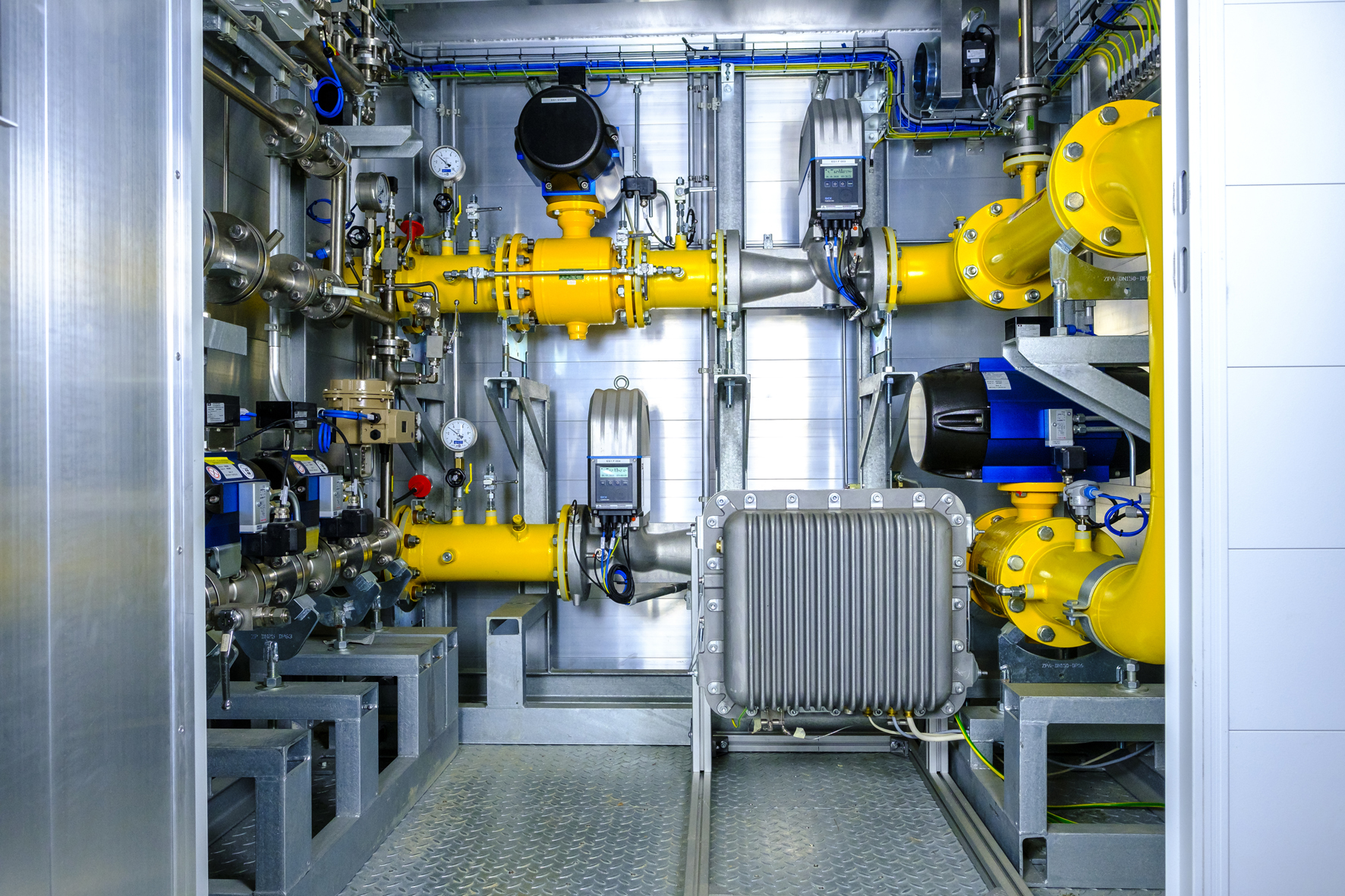

The spectrometer for the infrared-active components of the natural gas and the thermal conductivity sensor for hydrogen measurement are installed on a natural gas bypass at Fraunhofer ISE. The measuring device is housed in an explosion-proof case with cooling fins (bottom right in the picture).

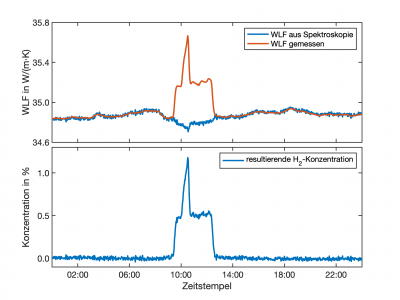

The upper part of the figure shows measurement data from the thermal conductivity sensor over time (red) during a hydrogen injection compared to the calculated thermal conductivity (WLF) (blue), which is based on the gas composition determined from the spectroscopic data. The infrared spectrometer does not detect hydrogen! Therefore, the H2 concentration can be determined from the difference between the measured thermal conductivity and the calculated thermal conductivity. The lower part shows the hydrogen concentration determined in this way during the addition of up to 1.2 percent H2 with an accuracy in the 100 ppm range.

About the project

The project “Gas efficiency – fast measurement technology for the efficient use of regeneratively produced gases” was funded by the Ministry of Economic Affairs, Labor and Housing Baden-Württemberg and the European Regional Development Fund (ERDF) in the funding period 2014 to 2020 with the leitmotif “Innovation and Energy Transition.”

Find out more on the website of the Fraunhofer Institute for Physical Measurement Techniques IPM.

Press release of the Fraunhofer Institute for Physical Measurement Techniques IPM