H2-Loop

High-pressure calibration of gas meters used for hydrogen

State-approved test center

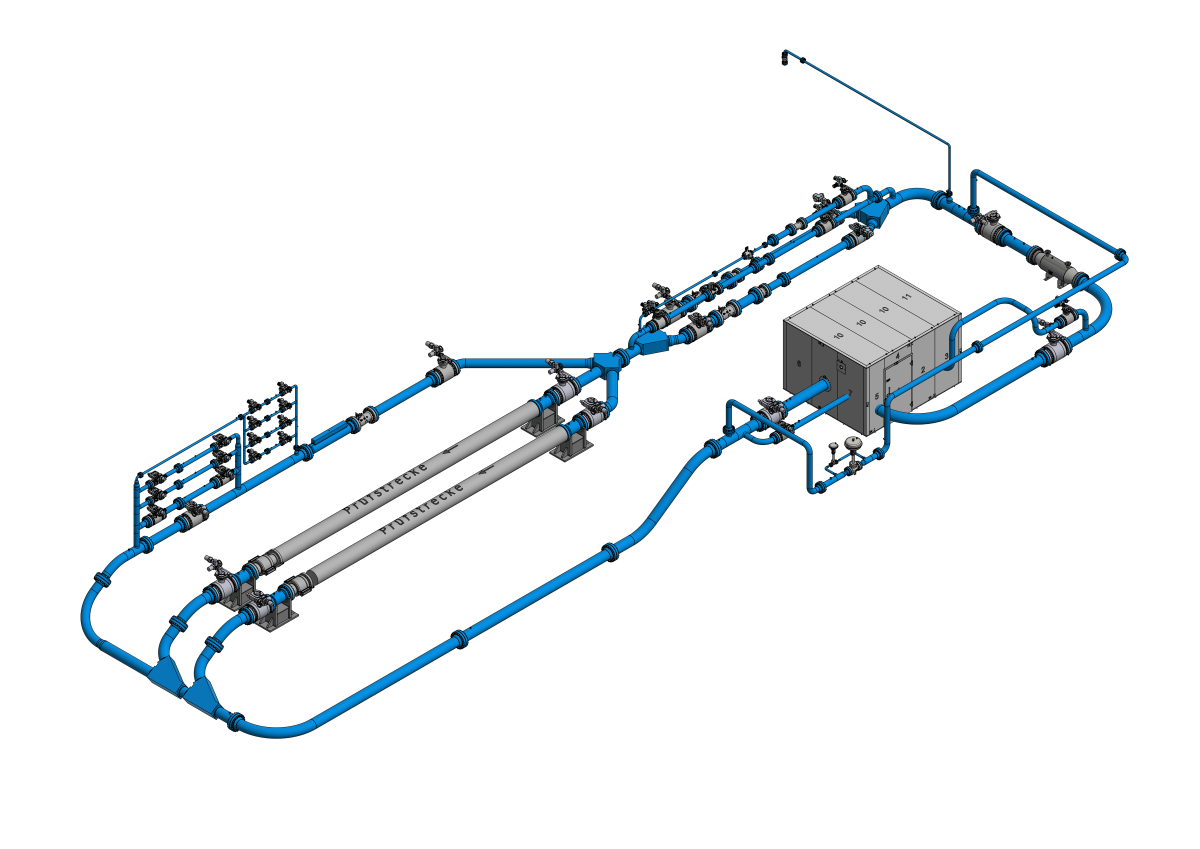

The H2-Loop is designed as a closed loop system in which hydrogen is transported in a controlled manner. After generating and stabilizing the flow in a high performance blower, which for safety reasons is located in a pressurized cabin, hydrogen is first passes the reference meter (with the standards), then the test samples before returning to the blower.

Technical data of the H2-Loop

- 2 test tracks à 11 m

- Nominal sizes of calibrated gas meters of DN 50 up to DN 300

- Flow rates of 5 – 6.500 m3/h*

- Pressure range of 8 bis 51 bar(a)

- Measure uncertainty: 0,2 – 0,3 %

- Continous monitoring of hydrogen purity

*Conformity assessments and custody transfer measurements can be performed in flow ranges from 16 – 6,500 m³/h.

Function

The function is based on comparing the measured values of the test samples at different flow rates and pressures with the measured values of the reference meters. Highly stable process conditions and the correction of known influences are prerequisites for highly accurate calibrations.

The H2-Loop is fed via a gas storage tank, similar to the RMA’s natural gas loop. This consists of bundles of hydrogen pressure vessels.

When the pressure is increased or filled, hydrogen is fed into the loop from this storage. Conversely, will the pressure be reduced, hydrogen is pressed back into the cylindrical hydrogen pressure vessel by means of a compressor. The hydrogen quality is being continuously monitored during the measurement.

You will find lots of useful information in our brochure.