RMA commissions the world’s largest hydrogen test bench for gas volume measurement

On Thursday, 29.06.2023, more than 100 guests of the RMA ceremoniously put the H2 test bench, the world’s largest test bench for hydrogen, into operation. Among the guests were the Vice President of the Physikalisch-Technische Bundesanstalt (PTB), Prof. h.c. Dr.-Ing. Frank Härtig, the CEO of the economic region Ortenau Nectanet, Mr. Dominik Fehringer, and the Managing Director of the IHK Südlicher Oberrhein, Dr. Dieter Salomon. They all congratulated the RMA on its new product, without which there can be no functioning hydrogen infrastructure. With this and other products, solutions and innovations, RMA is actively helping to shape the energy transition.

A milestone in the hydrogen economy

Gas is gas – unfortunately not! Hydrogen behaves differently to natural gas, for example, when it comes to determining gas quantities. A new high-pressure gas test bench for flow meters had to be designed and built in order to determine hydrogen gas quantities precisely: the H2 test bench from RMA is the world’s first and largest gas flow meter of its kind. The calibration of gas meters with flow rates of up to 6,500m³/h of pure hydrogen and 51bar pressure is now a reality.

Necessity for H2-Ready recognized early on

RMA recognized early on that the energy transition would not succeed without hydrogen. After the 2015 climate conference, RMA held an internal strategy meeting to set the necessary course for a hydrogen-ready product portfolio. Implementation began in 2019 with the upgrading of “H2-ready” fittings and the design of the hydrogen test bench, the largest in the world.

BMBF funding came at the right time

At the same time, the Federal Ministry of Education and Research (BMBF) began planning the largest funding initiative to date on the subject of the energy transition, the hydrogen flagship projects; a key contribution to the implementation of the National Hydrogen Strategy. In addition to H2Giga and H2Mare, the TransHyDE lead project focuses on the development, evaluation and demonstration of hydrogen transportation technologies. The BMBF nominated the RMA as coordinator of the TransHyDE project Safe Infrastructure, one of 9 projects in total. In addition to new concepts for safe components for a hydrogen infrastructure, as well as sensor technology for monitoring hydrogen storage facilities, pipelines and connection points, a central component is the development and commissioning of a calibratable hydrogen test bench. This milestone has now been reached with the commissioning of the H2 test bench.

The technical data is impressive

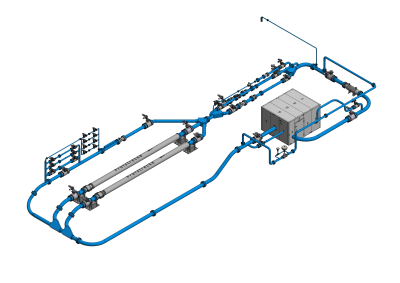

With two test lines, a minimum flow rate of 5m³/h and a maximum flow rate of 6,500m³/h, pressures of minimum 8 and maximum 51bar and nominal widths for internal pipe diameters and fitting connection dimensions from DN50 to DN300, the technical specifications of the H2 test bench are impressive. The measurement uncertainty of the calibration value of a meter is 0.2-0.3%. The hydrogen test bench is now available for research and testing purposes.

The hydrogen test bench of the RMA | Photo: WD GmbH – Advertising & Design

Schematic layout of the H2 test bench

Two high-pressure gas test benches from RMA complement each other perfectly

The hydrogen test bench completes the RMA portfolio

the RMA portfolio. Together with the

natural gas test bench, the hydrogen test bench forms

the new twin pair:

the TwinLoop.

LNG terminals also included

Large quantities of gas, including hydrogen gas and hydrogen-based energy sources, will have to be imported in the future. The inauguration ceremony for the first German liquefied natural gas terminal in Wilhelmshaven took place in December 2022. RMA made a significant contribution to the construction of the LNG terminal by supplying its components (ball valves, actuators and insulating pieces). As part of the now approved TransHyDE project LNG Terminals: Sustainable use with hydrogen, this conversion is now being scientifically investigated. The components installed in the RMA already correspond to the future and are suitable for hydrogen.

At RMA, the future has already begun today

RMA is a second-generation, family-run company that operates worldwide and has grown considerably over the years.

The group of companies with 24 companies employs around 900 people worldwide with an annual turnover of 150 million euros.

100% H2-compliant products, components and system solutions for hydrogen, water, oil, gas and district heating are designed, manufactured and sold at locations in Europe, North America, Asia and the Middle East.

Service and engineering services as well as software products for monitoring measurement systems round off the RMA product portfolio.

With these first-class products and highly qualified employees, it makes a decisive contribution to the success of its customers. RMA will continue to set new standards in the areas of innovation, quality and efficiency of its products in the future. Its goal is and remains to develop holistic solutions with and for its customers with its products and flexibility. In order to achieve these goals, RMA has set the decisive course in recent years with the expansion of its production sites and sales activities as well as the development of new products and, last but not least, the new hydrogen test bench.

Further information:

On the subject of hydrogen

About the hydrogen test bench

Hydrogen pilot projects: Homepage

Hydrogen pilot projects: TransHyDE: Hydrogen transportation

The TransHyDE lead project is funded by the Federal Ministry of Education and Research (BMBF).

Photo: Joachim Eiermann

Photo: WD GmbH – Advertising & Design